Polyurethane Injection Versus Replacement for Industrial Slab Repair

Polyurethane injection lifts and stabilizes sunken but structurally sound industrial slabs quickly with minimal downtime, while complete replacement addresses severely damaged or compromised slabs through demolition and new concrete installation, requiring extensive time and operational disruption.

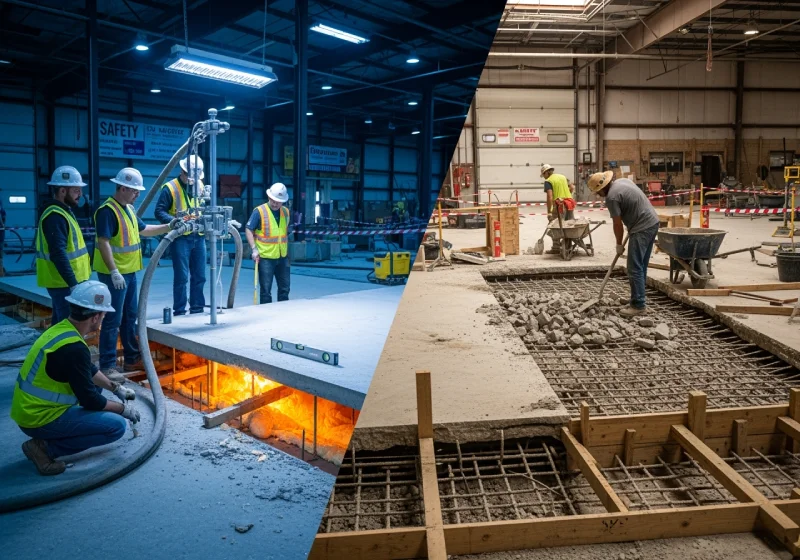

Industrial facilities facing concrete slab problems must choose between repair methods that dramatically differ in cost, downtime, and disruption. Polyurethane foam injection offers a minimally invasive approach that lifts sunken slabs and fills voids beneath the surface. Complete slab replacement provides a fresh start through demolition and new concrete installation.

Understanding the strengths, limitations, and ideal applications of each method helps facility managers make informed decisions that balance repair effectiveness with operational requirements. Superior Grouting specializes in concrete leveling solutions that restore industrial slab stability while minimizing downtime and disruption to your operations.

Key Takeaways

- Polyurethane injection repairs sunken slabs in 1-2 hours with minimal operational disruption through small injection holes, while replacement requires days to weeks of downtime for demolition, installation, and curing of new concrete.

- Injection costs 30-50% of replacement expenses when considering direct repair costs plus indirect costs from operational downtime, making it highly cost-effective for slabs that remain structurally sound but have settled or developed voids.

- The expanding foam fills voids and strengthens underlying soil while lifting slabs, providing 10-20+ years of moisture-resistant durability, whereas replacement durability depends entirely on proper soil preparation and installation quality.

- Polyurethane injection works best for sunken or uneven slabs with soil voids where the concrete remains structurally intact, while replacement becomes necessary only when slabs suffer extensive cracking, breaking, or structural compromise beyond repair.

- The minimal surface disruption from small injection holes allows facilities to resume normal operations within hours, contrasting sharply with replacement's heavy equipment, demolition debris, and extended closures that halt production.

- Choosing between methods depends on slab condition assessment, available downtime windows, budget constraints, and underlying soil stability issues, with injection serving as the preferred solution in most industrial slab repair scenarios.

Understanding Polyurethane Injection Technology

Polyurethane foam injection represents a modern approach to industrial slab repair that addresses settlement and void problems without removing existing concrete. This method combines chemical engineering with foundation repair expertise to deliver fast, effective results.

How Polyurethane Injection Works

The polyurethane injection process begins with a thorough assessment of the slab condition and void locations beneath the surface. Technicians drill small holes through the concrete, typically 5/8 inch in diameter, at strategic locations determined by void mapping and settlement patterns.

The injection process involves these key steps:

- Drilling precisely located injection points through the slab

- Inserting injection ports into each drilled hole

- Mixing two-component polyurethane that reacts immediately upon combining

- Injecting the expanding foam beneath the slab through specialized equipment

- Monitoring lift rates and foam expansion in real-time

- Stopping injection before over-lifting occurs as foam continues expanding briefly

- Patching injection holes to match surrounding concrete

The polyurethane foam expands rapidly after injection, filling voids from the bottom up while generating pressure that lifts the slab. The foam's expanding properties require skilled technicians who understand expansion rates and can achieve precise elevation control.

Material Properties and Performance

Polyurethane foam used in slab repair differs significantly from insulation foam. Industrial-grade structural foam features:

- High compressive strength supporting heavy loads indefinitely

- Closed-cell structure preventing water absorption

- Chemical resistance to soil acids and alkaline conditions

- Lightweight composition adding minimal weight to compromised soil

- Rapid cure time reaching full strength in 15-60 minutes

The closed-cell structure prevents water penetration even in saturated soil conditions. The material won't wash away, erode, or degrade from water exposure. Polyurethane foam weighs approximately 2-4 pounds per cubic foot compared to concrete at 150 pounds per cubic foot, adding negligible load to already compromised soil.

Soil Stabilization Benefits

Beyond simply lifting slabs, polyurethane foam provides genuine soil stabilization by filling and sealing voids that allowed the original settlement, compressing loose soil to increase its density and bearing capacity, creating a moisture barrier preventing future water intrusion, and bonding with soil particles forming a composite mass stronger than either material alone. This stabilization addresses the root cause of settlement rather than just correcting the symptom.

Complete Slab Replacement Process

Complete slab replacement involves removing existing concrete and installing entirely new slabs. This comprehensive approach addresses severe damage that lifting methods cannot repair.

Demolition and Removal

The replacement process begins with demolition of the existing slab:

- Closing the affected area and relocating operations

- Cutting and breaking the concrete into manageable sections

- Removing debris and hauling it to disposal facilities

- Excavating to proper depth for new slab installation

Demolition creates significant noise, dust, and vibration that disrupts nearby operations. Heavy equipment including jackhammers, concrete saws, and loaders operates throughout the demolition phase.

Subgrade Preparation

After removing the old slab, contractors must properly prepare the subgrade. This critical phase determines whether the new slab will perform better than its predecessor:

- Evaluating and addressing soil conditions that caused original failure

- Removing unsuitable soil and replacing with engineered fill

- Compacting in layers with verified density testing

- Installing vapor barriers and reinforcement as specified

- Ensuring proper drainage and base preparation

Inadequate subgrade preparation dooms the new slab to repeat the problems of the original. Proper attention to soil conditions that caused original failure prevents recurrence.

Concrete Installation and Curing

Pouring and finishing new concrete requires careful attention to specifications:

- Mixing concrete to specified strength and characteristics

- Placing concrete in planned sequences to avoid cold joints

- Finishing the surface to required flatness

- Applying curing compounds or coverings

- Protecting from temperature extremes during curing

Concrete reaches handling strength in 24-48 hours but requires 7 days to reach design strength and 28 days for full cure. The facility cannot resume normal operations until concrete achieves adequate strength for anticipated loads.

Comparative Analysis: Injection Versus Replacement

Understanding how polyurethane injection and replacement compare across critical factors helps facility managers choose the optimal repair approach.

Speed and Downtime Comparison

Time required for each repair method dramatically affects operational impact:

Polyurethane Injection Timeline:

- Site preparation and mobilization: 1-2 hours

- Drilling and injection work: 2-6 hours depending on area

- Foam cure time: 15-60 minutes

- Return to full operation: Same day, often within 2-4 hours total

Replacement Timeline:

- Demolition and debris removal: 1-3 days

- Subgrade preparation and compaction: 2-5 days

- Concrete placement and initial cure: 1 day placement, 7 days minimum cure

- Return to full operation: 10-14 days minimum, often longer

The contrast in downtime becomes especially significant for facilities operating on tight schedules or handling time-sensitive materials. A facility losing $10,000 per day in lost production faces $20,000 in downtime costs for injection versus $120,000 for replacement based on typical timelines.

Cost Analysis

Direct repair costs represent only part of the total financial impact. A comprehensive cost comparison must include:

| Cost Factor | Polyurethane Injection | Complete Replacement |

| Direct Repair Cost | Moderate ($8-15 per sq ft) | High ($15-35 per sq ft) |

| Demolition/Disposal | None | $3-6 per sq ft |

| Lost Production Time | Minimal (4-8 hours) | Extended (10-14+ days) |

| Material Costs | Foam materials | Concrete, reinforcement, fill |

| Equipment Rental | Specialized injection equipment | Heavy demolition and placement equipment |

| Site Restoration | Minimal patching | Complete area restoration |

| Total Cost Impact | 30-40% of replacement | 100% baseline |

Indirect costs from operational disruption often exceed direct repair expenses. Manufacturing facilities, warehouses, and distribution centers losing thousands of dollars per hour in downtime find injection's speed advantage translates directly to significant cost savings.

The cost differential increases when considering repeat repairs. Replacement that fails to properly address soil issues may require additional work within years, while properly executed injection provides decades of service without recurring costs.

Durability and Longevity

Both methods can provide long-term solutions when properly executed, but their durability depends on different factors:

Polyurethane Injection Durability:

- Material lifespan: 10-20+ years in typical conditions

- Performance depends on: proper void filling, adequate foam coverage, addressing water intrusion sources

- Moisture resistance: excellent due to closed-cell structure

- Soil improvement: strengthens underlying soil reducing future settlement risk

Replacement Durability:

- Material lifespan: 20-30+ years with proper installation

- Performance depends on: subgrade preparation quality, concrete mix design, proper curing, addressing original failure causes

- Moisture vulnerability: depends on installation quality and drainage

- Soil improvement: only if underlying issues are properly addressed during replacement

Replacement potentially offers longer lifespan when all factors align perfectly. However, the conditional nature of that advantage becomes significant. Many replacement projects fail to properly address the conditions that caused original failure, resulting in new slabs that develop problems within years.

Polyurethane injection's durability proves more predictable because the method inherently addresses soil voids and stabilizes the base. The foam's expansion fills gaps and strengthens soil regardless of original installation quality.

Surface Disruption and Accessibility

The physical impact of each repair method affects facility operations during and after the work:

Polyurethane Injection:

- Small 5/8 inch drill holes easily patched

- No debris or demolition waste

- Work area typically 10-20 feet around injection points

- Adjacent areas remain accessible during work

- No heavy equipment blocking access routes

- Minimal cleanup required after completion

Replacement:

- Complete removal of affected slab section

- Large volumes of concrete debris requiring disposal

- Work area includes staging for equipment and materials

- Adjacent areas may be inaccessible due to equipment and safety zones

- Heavy equipment blocking access routes and doorways

- Extensive cleanup and site restoration after concrete cures

Facilities with limited access, ongoing operations in adjacent areas, or restrictions on heavy equipment find injection's minimal disruption especially valuable. The ability to maintain operations nearby while repair work proceeds reduces total business impact significantly.

Soil Stabilization Effectiveness

The effectiveness of each method at preventing recurrence depends on how well it addresses underlying soil problems:

Polyurethane injection actively stabilizes soil by:

- Filling voids that caused settlement

- Compressing loose soil increasing bearing capacity

- Creating a composite soil-foam mass

- Preventing water intrusion to the void space

Replacement potentially stabilizes soil through:

- Removing and replacing unsuitable soil

- Properly compacting base materials

- Installing drainage improvements

- Addressing water intrusion sources

The critical difference lies in execution reliability. Polyurethane injection inherently provides stabilization through the repair process itself. Replacement provides stabilization only when contractors properly execute all subgrade preparation steps, which represents an additional variable in project success.

When to Choose Polyurethane Injection

Polyurethane injection serves as the optimal solution for specific conditions commonly found in industrial facilities.

Ideal Conditions for Injection

Polyurethane injection works best when slabs meet these criteria:

Structural Integrity:

- Concrete remains intact without extensive cracking

- No large sections broken into multiple pieces

- Surface shows minimal spalling or degradation

- Reinforcement remains properly positioned and effective

Settlement Patterns:

- Uneven surfaces from differential settlement

- Sunken areas lower than original grade

- Tilting or sloping where level surfaces existed

- Gaps developing between slabs and walls or equipment pads

Underlying Causes:

- Soil voids from erosion or poor compaction

- Water intrusion washing away supporting soil

- Consolidation of fill materials under slab weight

- Organic material decomposition creating voids

Operational Requirements:

- Minimal downtime available for repairs

- Continued operation needed in adjacent areas

- Time-sensitive production schedules

- Limited access for heavy equipment

Facilities meeting these conditions achieve excellent results from polyurethane injection while minimizing operational impact.

Unsuitable Conditions for Injection

Polyurethane injection cannot effectively address extensively cracked concrete with cracks wider than 1/4 inch throughout, slabs broken into multiple separate pieces, severe surface degradation from chemical attack or freeze-thaw damage, structural failure from inadequate thickness or reinforcement, or active chemical contamination of soil beneath slab. These conditions require replacement or other structural interventions.

Real-World Applications

Industrial facilities successfully using polyurethane injection include warehouses with settlement from heavy forklift traffic or concentrated pallet loads, manufacturing facilities with production floors settling around heavy equipment, and distribution centers with sorting areas settling from constant conveyor vibration. These applications share common characteristics: structurally sound concrete that has settled due to soil issues, operational requirements for minimal downtime, and cost constraints favoring efficient repair methods.

When Replacement Becomes Necessary

While polyurethane injection handles most industrial slab problems, certain conditions require complete replacement.

Severe Structural Damage

Replacement becomes necessary when concrete suffers damage beyond lifting capabilities:

Extensive Cracking:

- Network of interconnected cracks throughout the slab

- Cracks wider than 1/4 inch

- Cracks that continue growing despite repairs

- Cracking pattern indicating structural failure rather than settlement

Broken Sections:

- Slab broken into separate pieces

- Large sections that have completely separated

- Areas where pieces have shifted independently

- Fragmented sections from heavy impact damage

Surface Deterioration:

- Severe spalling exposing reinforcement

- Chemical attack degrading concrete strength

- Freeze-thaw damage causing surface breakdown

- Alkali-silica reaction compromising concrete integrity

These conditions indicate concrete that has reached the end of its service life or suffered damage that lifting cannot address.

Design Inadequacy

Some slabs fail not from external factors but from inadequate original design:

- Thickness insufficient for current loads

- Reinforcement inadequate for operational stresses

- Concrete strength too low for application

- Joint spacing inappropriate causing excessive cracking

Design inadequacy requires replacement with properly engineered specifications. Lifting an inadequately designed slab doesn't address the fundamental capacity limitations.

Multiple Failed Repair Attempts

Slabs that have undergone multiple repair attempts without lasting success often need replacement:

- Previous injection repairs that failed to hold

- Multiple patching attempts with continued deterioration

- Repairs addressing symptoms rather than causes

- Escalating repair frequency indicating fundamental problems

At some point, continued repair attempts cost more than replacement while providing diminishing returns. Recognizing this threshold prevents wasting resources on unsuccessful repair cycles.

Making the Right Choice for Your Facility

Selecting between polyurethane injection and replacement requires evaluating your specific situation against multiple criteria.

Decision Framework

Use this framework to guide your repair method selection:

| Evaluation Criteria | Favor Injection | Favor Replacement |

| Slab Condition | Structurally sound, settlement issues | Extensively cracked or broken |

| Available Downtime | Limited (hours to 1-2 days) | Extended (2+ weeks) |

| Budget Constraints | Tight budget, cost-sensitive | Budget allows comprehensive repair |

| Settlement Cause | Soil voids, erosion, consolidation | Design inadequacy, structural failure |

| Operational Impact Tolerance | Cannot tolerate extended closure | Can accommodate shutdown period |

| Previous Repair History | First intervention or successful past repairs | Multiple failed repair attempts |

| Surface Condition | Good to fair concrete surface | Severely degraded surface |

Most industrial slab problems fall into categories favoring injection. The combination of cost effectiveness, minimal downtime, and proven performance makes injection the preferred choice in the majority of cases.

Professional Assessment Value

Professional evaluation by experienced concrete repair specialists provides critical input for decision-making. Qualified professionals accurately diagnose root causes, identify underlying soil conditions, evaluate structural integrity, recommend appropriate repair approaches, and provide realistic cost and timeline estimates.

Attempting to self-diagnose or select repair methods without professional input risks choosing inappropriate solutions. Professional assessment cost represents a small fraction of total repair expenses while significantly improving outcome probability.

Long-Term Considerations

Beyond immediate repair needs, consider long-term facility plans. Facilities with short remaining lifespan (5 years or less) favor injection's lower cost. Long-term occupancy may justify replacement's comprehensive approach. Plans for expansion or modification affect repair scope decisions.

Increasing future loads may require replacement with enhanced design. Decreasing operational intensity may make injection adequate for remaining service life. Budget cycles and operational cost savings from reduced downtime also shift total cost comparison.

Maintenance After Repair

Regardless of repair method chosen, proper maintenance extends repair effectiveness and prevents recurrence.

Post-Injection Maintenance

Facilities repaired with polyurethane injection should monitor repaired areas for any new settlement, address water intrusion sources that contributed to original problems, maintain drainage systems, inspect regularly for cracks or deterioration, and control loads to remain within slab design capacity.

Post-Replacement Maintenance

New concrete slabs require attention during the critical first year. Protect from excessive loads during full curing, apply appropriate sealers once concrete fully cures, monitor for cracking when most problems appear, address drainage issues immediately, and conduct regular inspections during first two years.

Preventive Strategies

Implement preventive strategies to reduce future problems:

- Regular drainage system inspection and cleaning

- Proper load distribution using adequate bearing pads

- Training equipment operators in floor-friendly practices

- Monitoring for early signs of settlement

- Addressing water leaks immediately when discovered

Conclusion

Polyurethane injection and complete replacement represent different approaches to industrial slab repair. Injection provides fast, cost-effective repair for slabs that remain structurally sound but have settled due to soil voids or erosion. Replacement addresses severe structural damage or design inadequacy through comprehensive slab renewal.

Most industrial slab problems fall into categories where polyurethane injection delivers superior results. The combination of minimal downtime, lower total cost, and proven long-term performance makes injection the preferred solution for most facilities. Replacement becomes necessary only when concrete has suffered extensive structural damage.

Professional assessment by experienced concrete repair specialists ensures selection of the most appropriate repair approach. If your industrial facility faces concrete slab settlement, uneven surfaces, or foundation problems, professional evaluation determines the optimal repair approach. Contact Superior Grouting to discuss your concrete leveling needs and learn which repair method best suits your facility requirements.