How Cellular Grout Reduces Loads on Weak Soils

Cellular grout reduces loads on weak soils through its low density (30-70% lighter than conventional materials), creating a lightweight cellular matrix that distributes stresses evenly, provides buoyancy in saturated conditions, and minimizes lateral pressures while filling voids to prevent settlement.

Weak soils present fundamental challenges for construction projects. Soft clays, organic deposits, loose fills, and saturated sands lack the strength to support structures without excessive settlement or failure. Traditional solutions like soil replacement, deep foundations, or surcharge preloading prove costly, time-consuming, and often impractical for many sites.

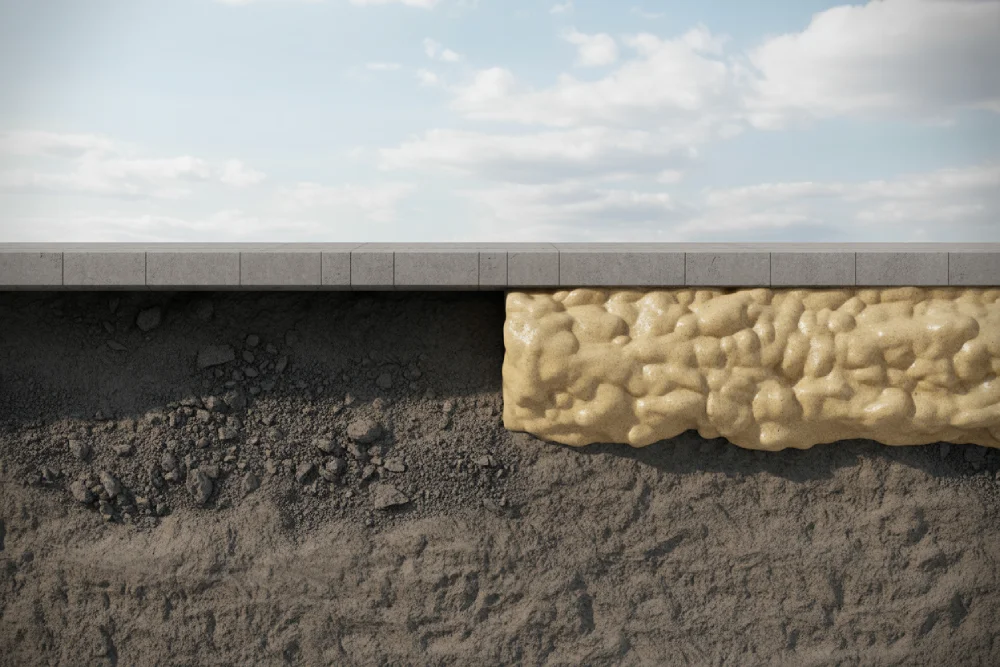

Cellular grout offers an alternative approach that works with weak soils rather than fighting against them. By replacing heavy fill materials with ultra-lightweight cellular concrete or foam grout, projects dramatically reduce the loads imposed on underlying weak soils. The material's unique cellular structure distributes stresses uniformly while its low density prevents the excessive loading that causes settlement and bearing capacity failures.

This lightweight solution enables construction on sites previously considered unbuildable without extensive ground improvement. Embankments, approach fills, utility trenches, and foundation systems can be built using cellular grouting without overstressing weak soils that would fail under conventional construction materials and methods.

Key Takeaways

- Cellular grout achieves densities of 25-100 pounds per cubic foot compared to 140-150 for conventional concrete, reducing imposed loads by 30-85% and preventing overstressing of weak soils that would fail under traditional fill materials or structural elements.

- The cellular matrix structure created by air bubbles distributed throughout the material spreads applied loads over wider areas, reducing stress concentrations that cause localized bearing failures and excessive settlement in weak or compressible soil layers beneath foundations and embankments.

- Buoyancy effects in water-saturated weak soils reduce effective weight of cellular grout by up to 60%, with the material's low density approaching that of water and creating near-neutral buoyancy that minimizes downward forces on soft clays and organic deposits.

- Lateral earth pressures on retaining walls and foundation elements decrease proportionally with reduced fill density, with cellular grout generating 50-75% less horizontal stress than conventional fill materials and enabling lighter structural designs or improving stability factors for existing installations.

- Void filling capabilities stabilize weak soils by occupying spaces where water and compressible materials would otherwise allow movement, with the solidified cellular mass preventing further subsidence and creating a more uniform load-bearing platform for structures and infrastructure systems.

- Cost savings from eliminating deep foundations, reducing structural requirements, and accelerating construction timelines often offset higher material costs, with cellular grout proving economical for projects on weak ground conditions where conventional approaches require extensive earth work or foundation improvements.

Understanding Weak Soil Challenges

Recognizing the specific problems weak soils create helps explain why cellular grout provides effective solutions where traditional materials fail.

Characteristics of Weak Soils

Weak soils encompass various materials sharing common problematic properties. Soft clays with high water content and low shear strength compress under load and provide minimal bearing capacity. Organic soils containing decomposed plant matter are highly compressible and continue settling for years after loading. Loose sands and silts lack the particle interlocking that creates strength in denser granular materials.

These soil types exhibit several behaviors that threaten structures:

- Low bearing capacity: Cannot support typical structural loads without excessive settlement or punching failure

- High compressibility: Undergo large volume reductions when loaded, causing structures to settle

- Long consolidation times: Settlement continues over months or years as water slowly drains from compressed soil

- Variable properties: Strength and compressibility change significantly over short distances complicating design

- Susceptibility to disturbance: Construction activities can further weaken already marginal soils

Projects encountering these conditions traditionally face difficult choices between expensive solutions or abandoning the site entirely.

Conventional Solutions and Limitations

Traditional approaches to weak soil construction involve either strengthening the soil or bypassing it with deep foundations. Each method carries significant costs and limitations that restrict application.

Soil replacement excavates weak material and replaces it with engineered fill, creating competent ground for construction. This approach works but becomes prohibitively expensive when weak soils extend to significant depths. Disposal of excavated material creates environmental concerns and costs. Construction adjacent to existing structures cannot use excavation without risking damage from undermining.

Deep foundations extend through weak soils to bearing on competent materials at depth. Driven piles, drilled shafts, and micropiles work reliably but add substantial cost. Foundation systems alone can consume 20-40% of project budgets on weak soil sites. The foundations must extend through entire weak soil deposits, sometimes reaching depths of 50-100 feet, multiplying costs geometrically with weak soil thickness.

Surcharge preloading applies temporary loads that consolidate weak soils before construction, improving strength and reducing future settlement. This method requires months or years for consolidation to complete, delaying projects unacceptably. Not all weak soils respond favorably to preloading. The temporary surcharge material must be placed and removed, adding handling costs.

These limitations create demand for alternative solutions that work effectively without the cost, time, and complexity of traditional approaches.

Economic Impact of Weak Soil Construction

Building on weak soils without appropriate techniques leads to predictable and expensive consequences. Differential settlement cracks structures, damages utilities, and disrupts operations. Bearing capacity failures cause sudden structural collapse endangering lives and creating massive liability.

Repair costs typically exceed prevention costs by factors of 5-20 times. Emergency repairs disrupt operations creating indirect costs exceeding direct repair expenses. Insurance premiums increase after claims. Project reputations suffer affecting future opportunities.

These economic realities justify investment in proper weak soil solutions like cellular grouting that prevent problems rather than requiring later remediation. The analysis must consider total project lifecycle economics, not just initial construction costs.

How Cellular Grout Material Properties Reduce Loads

The fundamental characteristics of cellular grout create multiple mechanisms that lighten loads imposed on weak soils.

Ultra-Low Density Achievement

Cellular grout achieves its load reduction primarily through dramatically lower density than conventional construction materials. The cellular structure incorporates millions of tiny air bubbles throughout the cementitious or polymer matrix, creating a material that is 30-85% lighter than conventional concrete or soil fill.

The table below compares densities of cellular grout with conventional materials:

| Material Type | Typical Density (pcf) | Relative Weight | Load Reduction vs. Concrete |

| Conventional Concrete | 140-150 | 100% | Baseline |

| Compacted Granular Fill | 120-135 | 90% | 10-15% |

| Lightweight Aggregate Concrete | 90-110 | 70% | 30% |

| Cellular Grout (High Density) | 70-100 | 60% | 40% |

| Cellular Grout (Medium Density) | 40-70 | 40% | 60% |

| Cellular Grout (Low Density) | 25-40 | 25% | 75% |

This dramatic density reduction translates directly to reduced loads on underlying soils. A project replacing 10 feet of conventional fill (1,400 pounds per square foot) with low-density cellular grout (300 pounds per square foot) reduces soil loading by over 1,100 pounds per square foot, often making the difference between acceptable performance and bearing capacity failure.

Cellular Structure and Composition

The air bubble network creating cellular grout's lightweight properties results from either preformed foam addition during mixing or chemical reactions generating gas within the material. Both approaches create similar final structures with properties determined primarily by bubble size, distribution, and total air content.

Preformed foam methods inject stable foam into cementitious slurry during mixing. The foam bubbles remain intact through placement and curing, creating the final cellular structure. This approach provides excellent control over final density through foam injection rate adjustment.

Chemical foaming uses additives that react with cement or mix water generating gas bubbles in place. Aluminum powder reacting with alkaline cement paste produces hydrogen gas creating bubbles. Peroxide-based foaming agents decompose releasing oxygen. These methods work well for certain applications but provide less precise density control than preformed foam approaches.

Bubble size affects material properties beyond just density. Fine bubbles (0.1-1.0 mm diameter) create stronger materials at equivalent densities compared to coarse bubbles (2-5 mm). The increased surface area provides more structural continuity through the cement matrix between bubbles. However, smaller bubbles prove more difficult to generate and stabilize during mixing and placement.

Strength Despite Low Density

Despite densities approaching one-quarter of conventional concrete, cellular grout develops adequate compressive strength for many applications. Strengths ranging from 50 to 800 psi prove sufficient for utility trench fill, embankment construction, void filling, and certain foundation applications.

The cellular structure contributes to this favorable strength-to-weight ratio. Air bubbles distribute uniformly through the cement matrix creating a honeycomb structure where each cell wall carries load. This geometry proves structurally efficient, similar to honeycomb materials in aerospace applications.

Strength development continues over months as cement hydration progresses. Seven-day strengths typically reach 40-60% of 28-day values, with some gain continuing to 90 days and beyond. This ongoing strengthening means cellular grout placed today provides better support to overlying structures months later, helpful for long-term settlement reduction.

Load Reduction Mechanisms in Weak Soils

Multiple physical processes combine to reduce stresses imposed on weak soils by cellular grout compared to conventional materials.

Direct Weight Reduction

The most straightforward load reduction comes from simply placing less weight on weak soils. Every cubic yard of cellular grout weighing 50 pounds per cubic foot imposes 1,350 pounds per cubic yard. Conventional concrete at 150 pounds per cubic foot places 4,050 pounds per cubic yard on underlying soil, three times more load.

For large projects, these differences become enormous. A roadway embankment 1,000 feet long, 50 feet wide, and 10 feet high contains approximately 18,500 cubic yards of fill material. Using low-density cellular grout saves roughly 50 million pounds of load compared to conventional fill. This load reduction can make the difference between acceptable settlement (2-6 inches) and unacceptable settlement (12-24 inches) on weak soils.

The savings multiply in multilevel structures or deep fills where material thickness increases. Highway approach fills transitioning from grade to elevated structures sometimes require 30-50 feet of fill height. Using cellular grout at these depths prevents the massive loads that would overstress weak foundation soils causing excessive settlement or bearing failure.

Stress Distribution and Spreading

Beyond simple weight reduction, cellular grout's material properties improve how loads distribute into underlying soils. The slightly compressible cellular structure acts as a stress-absorbing layer, spreading concentrated loads over wider areas before they reach weak soils.

Point loads from utility connections, structural footings, or equipment concentrated in small areas create high stress concentrations in underlying soil. These stress peaks often exceed soil bearing capacity locally even when average stresses remain acceptable. Conventional fill materials transmit these concentrations directly downward with minimal spreading.

Cellular grout's slight compressibility allows it to deform elastically under concentrated loads, spreading stresses laterally before reaching weak soils. A point load creates a wider stress bulb in weak soil beneath cellular grout compared to beneath rigid conventional fill. This spreading reduces peak stresses that threaten bearing capacity while maintaining overall load support.

The stress distribution improvement proves particularly valuable for utility systems where pipe loads, valve vaults, and connection boxes create numerous point loads within fills over weak soils. Cellular grout accommodates these loads without creating failure zones that would develop in weak soils under conventional fill materials.

Buoyancy Effects in Saturated Conditions

When weak soils contain high water content or experience groundwater submergence, buoyancy reduces the effective weight of cellular grout dramatically. Water exerts upward pressure on submerged materials equal to the weight of water displaced (Archimedes' principle). Since cellular grout densities approach water density (62.4 pcf), buoyant forces can offset 50-80% of material weight in saturated conditions.

A cellular grout with 40 pcf dry density becomes effectively 22 pcf when fully submerged (40 minus 18 pcf buoyant force). This near-neutral buoyancy means cellular grout imposes minimal additional load on saturated weak soils even when placed in substantial thicknesses. Conventional concrete at 150 pcf becomes 87 pcf submerged, still imposing nearly four times more load than cellular grout.

Coastal projects, wetland crossings, and areas with shallow groundwater benefit dramatically from this buoyancy effect. Sites where saturated weak soils extend significant depths below the water table see effective stress increases of only 10-30 pounds per square foot from cellular grout fills compared to 80-100 pounds per square foot from conventional materials.

The buoyancy advantage continues functioning throughout the structure's service life as seasonal water table fluctuations occur. Conventional materials impose varying loads as buoyancy changes with water levels. Cellular grout's near-neutral buoyancy maintains consistent loads regardless of groundwater elevation, reducing cyclic stressing that degrades weak soils over time.

Reduced Lateral Earth Pressures

Lateral earth pressures from fill materials push horizontally against retaining walls, foundation walls, and adjacent structures. These horizontal forces create moments and stresses that must be resisted by structural elements or may cause instability if too large.

Lateral pressure magnitude depends directly on fill material density through the relationship: lateral pressure equals vertical pressure times lateral earth pressure coefficient. Since vertical pressure is proportional to material density, lateral pressure also scales directly with density.

Cellular grout generating one-third the vertical stress of conventional fill creates only one-third the lateral pressure. A 20-foot deep cellular grout backfill at 40 pcf generates approximately 350 pounds per square foot maximum lateral pressure at the base. Conventional fill at 120 pcf creates 1,050 pounds per square foot, three times larger.

This reduction enables lighter retaining wall designs, reduces foundation wall moments and reinforcing requirements, and improves stability of structures on weak soils where lateral loads contribute to bearing capacity and sliding resistance problems. Existing walls showing signs of distress from excessive lateral loads can be relieved by replacing backfill with cellular grout, often avoiding expensive wall reconstruction.

Applications Where Load Reduction Benefits Weak Soils

Different infrastructure types experience unique benefits from cellular grout's load-reducing properties.

Highway Embankments and Approach Fills

Highway construction frequently encounters weak soils in low-lying areas where roads must cross wetlands, floodplains, or soft valleys. Embankments and bridge approach fills impose substantial loads that cause excessive settlement or bearing failure in these weak soils.

Conventional solutions require either massive soil replacement extending to competent bearing layers (expensive and slow) or surcharge preloading and wick drains (time-consuming and unreliable). Both approaches delay projects and inflate costs significantly.

Cellular grout enables direct embankment construction over weak soils without extensive ground improvement. The reduced load matches existing soil bearing capacity, preventing excessive settlement. Approach fills connecting at-grade sections to elevated bridges can be constructed without the differential settlement that creates rough transitions and ongoing maintenance problems.

Construction proceeds quickly since cellular grout placement requires no extended consolidation periods. The material flows into place, self-levels, and gains adequate strength within days for pavement construction. This speed reduces construction timeline by months compared to preloading approaches.

Utility Trench Backfill

Utility installations cut trenches through existing ground, then backfill around pipes after installation. These trenches frequently penetrate weak soils where backfill weight can overstress surrounding ground causing settlement of adjacent structures, pavements, and utilities.

Conventional backfill using excavated soil or imported granular material weighs 100-135 pounds per cubic foot. Deep trenches in weak soil areas impose substantial loads that consolidate surrounding weak soils, creating settlement troughs extending beyond trench limits. Pavement over trenches settles differentially, creating rough riding surfaces and drainage problems.

Grouting services using cellular grout for utility trench backfill reduce these loads by 60-80% compared to conventional methods. The lightweight fill imposes minimal additional stress on weak soils adjacent to trenches. Settlement becomes negligible, preventing pavement distress and maintaining adjacent structure stability.

The flowable nature of cellular grout completely fills trench volumes including irregular areas around pipe appurtenances where conventional granular backfill leaves voids. This complete filling prevents future settlement from void collapse that creates sinkholes and utility damage in conventionally backfilled trenches.

Building Foundation Systems

Buildings on weak soils traditionally require deep pile or pier foundations extending to competent bearing strata. These foundation systems prove expensive, particularly for light structures like single-story warehouses, parking structures, or residential buildings where foundation costs become disproportionate to total building cost.

Cellular grout enables shallow foundation systems on weak soils by reducing loads to levels existing soils can support. The building's floor slab and grade beams rest on a cellular grout mat that distributes structural loads over large areas while imposing minimal additional load on underlying weak soils.

This approach works particularly well for large footprint structures where conventional deep foundations would require hundreds of piles. The cellular grout mat costs substantially less than deep foundation systems while providing adequate bearing for light to moderate building loads.

The system accommodates minor differential settlement that inevitably occurs in weak soils through the slight compressibility of cellular grout. This accommodation prevents the rigid structural distress that would occur with conventional foundation systems unable to tolerate any differential movement.

Levee and Dam Construction

Levees and dams often must be constructed across valleys containing weak soils deposited by the rivers they now control. Traditional earthen embankment construction creates massive loads that consolidate weak foundation soils, causing excessive settlement that reduces freeboard and threatens flood protection capacity.

Cellular grout levee cores or dam sections dramatically reduce foundation loading compared to conventional earthfill. A 30-foot high levee using cellular grout core with earthfill slopes weighs 40-60% less than all-earthfill construction. This weight reduction keeps foundation stresses within bearing capacity of weak soils while maintaining required hydraulic performance.

The reduced loads also decrease lateral spreading tendencies in soft foundation soils. Weak soils beneath heavy embankments can fail by lateral squeezing outward from beneath the load. Cellular grout's lower weight reduces these outward forces, improving stability against this failure mode.

Construction using cellular grout proceeds more rapidly than conventional methods requiring staged construction with consolidation monitoring between lifts. Projects can be completed in single construction seasons rather than requiring multiple years for proper consolidation, reducing costs and accelerating flood protection benefits.

Engineering Design Considerations

Successful cellular grout applications require proper engineering analysis and design specific to weak soil conditions and project requirements.

Bearing Capacity Analysis

Weak soils have limited ability to support loads without failing in bearing or settling excessively. Engineers must analyze whether reduced loads from cellular grout keep soil stresses within safe limits.

Bearing capacity depends on soil shear strength, foundation geometry, and applied loads. Standard bearing capacity equations (Terzaghi, Meyerhof, Hansen) calculate ultimate bearing capacity that would cause foundation failure. Allowable bearing capacity applies safety factors of 2.5-3.0 to ultimate values, providing margins against failure and limiting settlement to acceptable levels.

Analysis compares applied stresses from cellular grout and supported structures to allowable bearing capacity. When cellular grout reduces loads sufficiently that applied stresses remain below allowable values, the design proves feasible. If stresses still exceed capacity, either lower density cellular grout, thinner fills, or supplemental ground improvement become necessary.

The analysis must consider both immediate bearing failure and long-term consolidation settlement. Some weak soils possess adequate short-term bearing capacity but consolidate significantly over time. Predicting both immediate and time-dependent settlement ensures designs meet performance requirements throughout project service lives.

Settlement Prediction and Tolerance

All structures on weak soils experience some settlement as soils compress under load. The question becomes whether settlements remain within tolerable limits for the structure and its intended use.

The table below shows typical settlement tolerances for different structure types:

| Structure Type | Total Settlement Tolerance | Differential Settlement Tolerance | Time Frame for Concern |

| Highway Pavements | 4-6 inches | 1 inch per 50 feet | 1-5 years post-construction |

| Utility Pipes (Flexible) | 6-12 inches | 2-3 inches per 50 feet | 1-10 years post-construction |

| Single-Story Buildings | 2-4 inches | 0.5-1.0 inch per 50 feet | Construction through 5 years |

| Multi-Story Buildings | 1-2 inches | 0.25-0.5 inch per 50 feet | Construction through 10 years |

| Levees and Dams | 6-24 inches | Variable by design | Construction through 20 years |

Cellular grout's load reduction decreases both total and differential settlement. Projects that would experience 12-18 inches of settlement under conventional fill may settle only 3-6 inches with cellular grout, bringing performance within acceptable ranges without requiring extensive ground improvement.

Settlement predictions use consolidation theory (Terzaghi) for cohesive soils and relative density correlations for granular soils. Geotechnical investigations provide soil properties (compressibility, permeability, strength) needed for these analyses. Conservative assumptions about properties ensure predictions err toward overestimating rather than underestimating settlement.

Material Selection and Mix Design

Cellular grout density must be selected balancing load reduction benefits against strength requirements and cost considerations. Lower density reduces loads more effectively but provides less strength and costs more per unit volume due to higher foam content.

Projects requiring minimal strength (50-150 psi) like void filling, utility trench backfill, or lightweight fill can use very low densities (25-50 pcf) maximizing load reduction. Applications needing moderate strength (200-400 psi) for structural support or traffic loading require medium densities (50-70 pcf). Specialized structural uses demanding high strength (500-800 psi) need higher densities (70-100 pcf) sacrificing some load reduction for enhanced strength.

Mix proportioning affects both density and strength. Higher cement content increases strength at equivalent density but raises cost and shrinkage potential. Fly ash or slag additions improve long-term strength development and reduce costs but may slow early strength gain. Fiber reinforcement improves ductility and crack resistance for applications experiencing tensile stresses.

Field trials producing sample batches at proposed densities verify that specifications can be achieved reliably with available materials and equipment. Testing compressive strength, flowability, and stability ensures mixes perform as designed before large-scale production begins.

Quality Control and Verification

Maintaining consistent density and properties throughout placement ensures cellular grout performs as designed. Density directly determines load reduction, so variations translate to stress variations on underlying weak soils.

Field density testing uses nuclear density gauges, core sampling with volume and weight measurements, or pressure meters. Testing frequency typically ranges from one test per 50-100 cubic yards depending on project criticality and variability observed during placement.

Compressive strength testing on cylinder samples verifies adequate strength development. Samples cast during placement cure under field conditions, then test at specified ages (typically 7 and 28 days). Results confirming design strengths indicate proper mix proportioning and placement procedures.

Flow testing ensures cellular grout maintains adequate workability for complete void filling and self-leveling behavior. Flow cone tests measure viscosity and indicate when adjustments to water content or foam generation rate become necessary to maintain target properties.

Cost-Benefit Analysis for Weak Soil Sites

Economic evaluation often determines whether cellular grout proves viable compared to alternative weak soil solutions.

Direct Cost Comparisons

Cellular grout material costs range from $150-400 per cubic yard depending on density, compared to $50-100 per cubic yard for conventional fill materials. This 2-5 times cost premium appears disadvantageous until considering system costs rather than just material expenses.

Deep foundation systems that cellular grout eliminates cost $5,000-15,000 per structural foundation element. A building requiring 200 foundation piles at $8,000 each involves $1,600,000 in foundation costs. Cellular grout foundation mat supporting the same building might cost $400,000, saving $1,200,000 despite higher material unit costs.

Soil replacement excavating weak material and importing suitable fill costs $30-80 per cubic yard including excavation, disposal, and replacement. Projects requiring replacement of 10,000 cubic yards of weak soil cost $300,000-800,000. Cellular grout working with existing weak soils eliminates these excavation and disposal expenses entirely.

Time savings from cellular grout's rapid placement and strength gain reduce indirect costs significantly. Preloading and consolidation approaches may require 6-18 months for adequate soil improvement. Project carrying costs (financing, overhead, lost revenue) during these delays often exceed $50,000-200,000 per month. Cellular grout's 1-2 week placement and curing timeline saves millions in time-dependent costs on large projects.

Lifecycle Cost Considerations

Initial construction cost represents only part of total ownership cost over infrastructure service lives of 20-50 years. Maintenance, repair, and replacement costs dominate lifecycle economics for many projects.

Structures on weak soils experiencing excessive settlement require ongoing maintenance adjusting elevations, repairing cracks, and replacing damaged components. Highways over settling approaches need repeated pavement rehabilitation. Buildings on settling foundations need continuous releveling of floors and realignment of utilities. These maintenance costs accumulate to millions over decades.

Cellular grout's load reduction prevents or minimizes settlement, dramatically reducing lifecycle maintenance costs. Projects that would require major rehabilitation every 5-10 years under conventional construction may need only routine maintenance with cellular grout. Present-valuing these maintenance savings over 30-50 year service lives often justifies substantially higher initial construction costs.

Operational disruptions from settlement-related maintenance create indirect costs exceeding direct repair expenses. Highway lane closures for approach repair reduce capacity and delay travelers. Building shutdowns for foundation repairs lose rental income and disrupt operations. These disruption costs argue strongly for settlement prevention through proper weak soil solutions like cellular grout.

Risk Mitigation Value

Catastrophic failures from bearing capacity exceedance or excessive settlement create enormous financial and legal liabilities. Repair costs often exceed original construction costs by factors of 5-20 times. Liability claims from injuries or property damage reach millions. Reputational damage affects future project opportunities.

Cellular grout's load reduction provides quantifiable risk mitigation by maintaining stresses well below failure thresholds. Probability-adjusted cost models incorporating failure scenarios often show cellular grout proving economically superior to cheaper alternatives carrying higher failure risks.

Insurance costs reflect these risk considerations. Projects on weak soils using proper load reduction techniques like cellular grout may qualify for lower premiums compared to conventional construction approaching soil capacity limits. These insurance savings persist throughout project lifetimes, adding to lifecycle cost advantages.

Future Developments in Cellular Grouting Technology

Ongoing research and industry innovation continue improving cellular grout capabilities and applications for weak soil construction.

Advanced Foam Generation Systems

Foam quality and stability critically affect cellular grout performance. Modern foam generators produce more uniform bubble sizes with better stability, improving strength and reducing density variability compared to earlier equipment.

Computer-controlled systems monitor foam density and adjust injection rates automatically maintaining target air content despite variations in materials or ambient conditions. This automation improves consistency across large projects where manual control would create property variations.

Specialized surfactants creating more stable foam bubbles prevent bubble coalescence and collapse during mixing and placement. These chemical improvements allow cellular grout to be pumped longer distances or placed underwater without foam degradation that would compromise final properties.

Bio-Based Foaming Agents

Environmental concerns drive development of foaming agents from renewable resources rather than petroleum-derived chemicals. Plant-based proteins and natural surfactants create stable foams while reducing environmental impacts and supporting sustainability goals.

These bio-based materials perform comparably to conventional foaming agents while offering lower carbon footprints and reduced aquatic toxicity. As production scales increase and costs decrease, bio-based foaming agents will likely become standard rather than specialty alternatives.

Self-Monitoring Smart Cellular Grout

Embedding sensors within cellular grout during placement creates smart materials reporting their own condition continuously. Strain gauges, temperature sensors, and pressure transducers provide real-time data on stress levels, settlement, and structural behavior.

This monitoring identifies developing problems early when minor interventions prevent major failures. Cellular grout showing unexpected stress increases or settlement rates triggers investigation before structural damage occurs. The approach proves particularly valuable for critical infrastructure on weak soils where failure consequences justify monitoring investment.

Conclusion

Cellular grout reduces loads on weak soils through multiple mechanisms working together to prevent bearing failure and excessive settlement. Its ultra-low density (25-100 pcf) weighs 30-85% less than conventional materials, directly reducing imposed stresses. The cellular structure distributes loads uniformly, preventing stress concentrations. Buoyancy in saturated conditions reduces effective weight by 50-80%. Reduced lateral pressures benefit retaining structures and adjacent facilities.

These load reduction benefits enable construction on weak soil sites that would otherwise require expensive deep foundations, extensive soil replacement, or lengthy consolidation periods. Highway embankments, utility systems, building foundations, and water infrastructure become feasible and economical using cellular grout where conventional approaches prove impractical.

Proper engineering design ensures cellular grout properties match specific weak soil conditions and project requirements. For projects facing weak soil challenges, contact Superior Grouting to discuss how cellular grouting can reduce loads, prevent settlement, and enable cost-effective construction. Density selection, strength verification, and quality control deliver reliable performance throughout infrastructure service lives.